ORO KOI:

ULTRASOUND

DEFROSTING

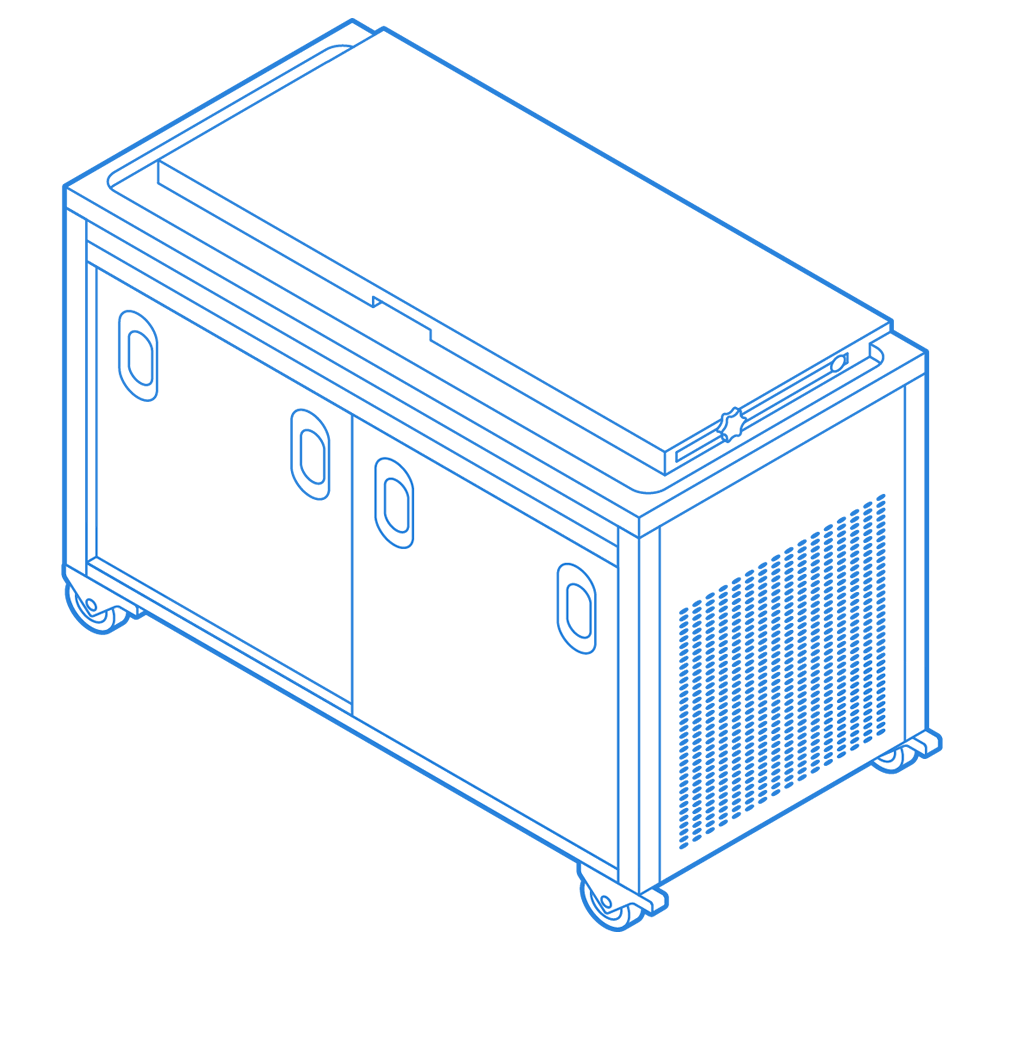

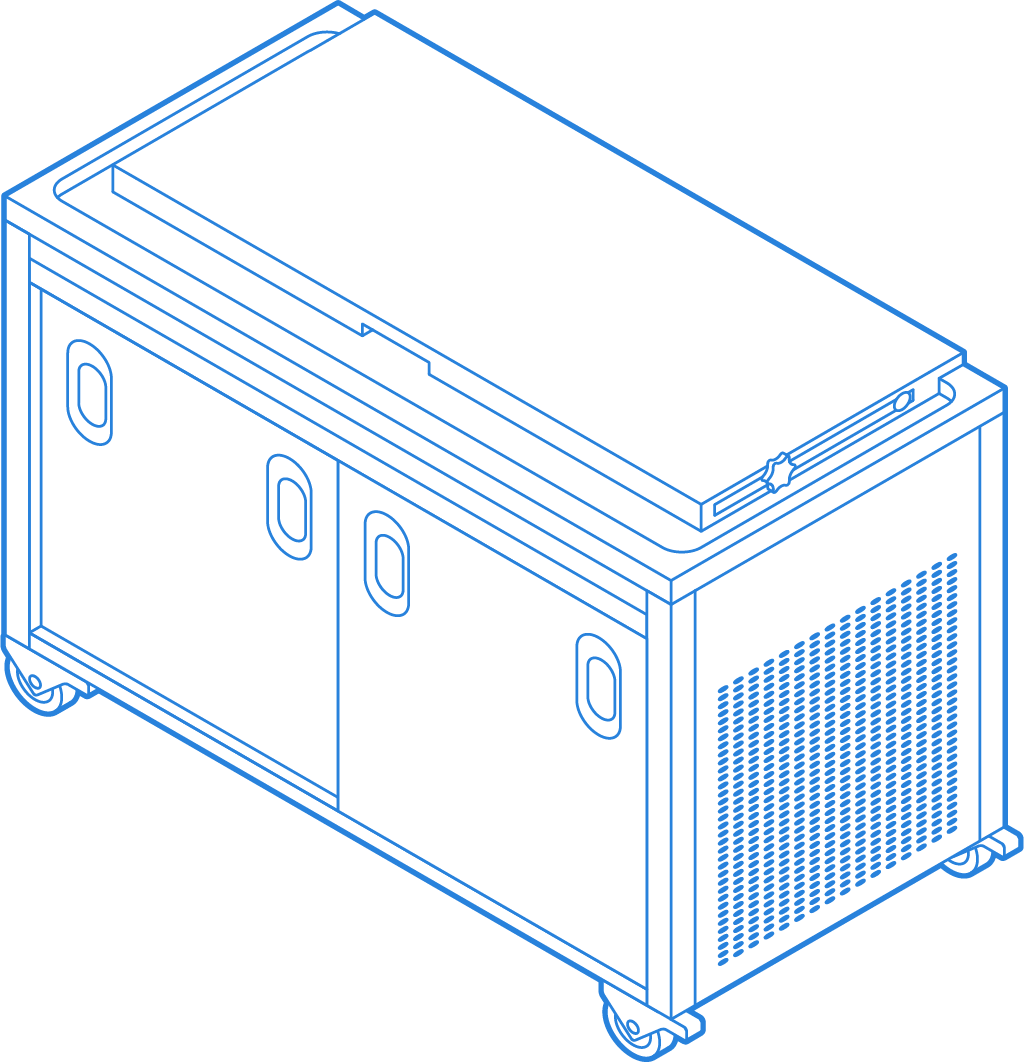

The machinery we are presenting to the market it’s an operational tool which provide a defrosting technique named IQT (Individual Quick Thawing) with ultrasound in a water bath; through the natural phenomon of sonic waves that are breaking ice crystals rather than thermically melting them.

.

We propose multiple specific programs (fish, meat…) that can be selected by a touch screen display (or a computer) and activate the thawing process.

.

Meanwhile, being the water bath always set at

a T range between 0-4 °C, there will be no issues about “forgetting” the product in the machine… as it works also as a fridge.

ORO KOI:

ULTRASOUND

DEFROSTING

The machinery we are presenting to the market it’s an operational tool which provide a defrosting technique named IQT (Individual Quick Thawing) with ultrasound in a water bath; through the natural phenomon of sonic waves that are breaking ice crystals rather than thermically melting them.

We propose multiple specific programs (fish, meat…) that can be selected by a touch screen display (or a computer) and activate the thawing process.

Meanwhile, being the water bath always set at

a T range between 0-4 °C, there will be no issues about “forgetting” the product in the machine… as it works also as a fridge.

What are the main advantages?

Food Safety

We grant the defrosting according to all international regulations:

defrosting and preservation occurs always in the T range of 0-4 °C.

The analysis on Listeria are also proving the partial sanitizing and bacteriostatic effect of ultrasound waves. This has a huge impact on determination of shelf life of raw products.

Meat taste and texture

The chemical and phyisical analysis we run on salmon, are showing that the products that we selected when they are defrosted by ultrasounds, are better than fresh and refrigerated salmon – TVB-N, TMA and Peroxide levels are always better in comparison with traditionally defrosted products and with normal fresh refrigerated salmon. Morover, the same analysis run after 4 days from defrosting, are showing that ultrasound-assisted thawed salmon retains more stable and parameters (with minimun change).

As well, the hystologic analysis are proving that meat texture of ultrasound-assisted thawed products is perfectly suitable for gastronomy involving raw fish (sushi, etc.), as the texture itself is not damaged as it is with traditional defrosting.

Fast processing time (IQT)

Processing time for defrosting is cut-down from 1/2 to 1/8 up to 1/10 of the normal time needed, depending on the size and regardless of starting temperature (-40 °C or -20 °C) of the product. Eg.: to defrost a 5/6 kg salmon, normally occurs around 45 hours in a refrigerating room 0-4 °C, while with our machine it takes only 4,5 hours with the same temperature..

“Custom-made” approach and pre/post sales assistance

Size of machine and optionals are based on the customers needs. Continuous monitoring – by remote-control – of thermic bath temperatures, recording and possibility to check the production cycles sustained, keeping traceability and calculating products consumption.

Financials, logistics and enviromental benefits

With the adoption of frozen logistic, the frozen food longer shelf life, there are no risks of late or missing deliveries which revert into turnover loss, as these are mainly issues of fresh/refrigerated logistic. Besides the possibility of better management of stocks,

savings on product waste, there’s also the possibility to save money on deliveries and product purchasing. Oro Koi can offer with it’s own company network, the 4PL business model: we buy on customer’s direction, we process (we can freeze, if requested), we stock, we prepare the product, we deliver it and we invoice it only when the product is being shipped and delivered. Last but not least, the possibility of managing frozen product, not only help in controlling prices and buying during productions peaks, but to respect seasonality of products.

What are the main advantages?

Food Safety

We grant the defrosting according to all international regulations:

defrosting and preservation occurs always in the T range of 0-4 °C.

The analysis on Listeria are also proving the partial sanitizing and bacteriostatic effect of ultrasound waves. This has a huge impact on determination of shelf life of raw products.

Meat taste and texture

The chemical and phyisical analysis we run on salmon, are showing that the products that we selected when they are defrosted by ultrasounds, are better than fresh and refrigerated salmon – TVB-N, TMA and Peroxide levels are always better in comparison with traditionally defrosted products and with normal fresh refrigerated salmon. Morover, the same analysis run after 4 days from defrosting, are showing that ultrasound-assisted thawed salmon retains more stable and parameters (with minimun change).

As well, the hystologic analysis are proving that meat texture of ultrasound-assisted thawed products is perfectly suitable for gastronomy involving raw fish (sushi, etc.), as the texture itself is not damaged as it is with traditional defrosting.

Fast processing time (IQT)

Processing time for defrosting is cut-down from 1/2 to 1/8 up to 1/10 of the normal time needed, depending on the size and regardless of starting temperature (-40 °C or -20 °C) of the product. Eg.: to defrost a 5/6 kg salmon, normally occurs around 45 hours in a refrigerating room 0-4 °C, while with our machine it takes only 4,5 hours with the same temperature..

“Custom-made” approach and pre/post sales assistance

Size of machine and optionals are based on the customers needs. Continuous monitoring – by remote-control – of thermic bath temperatures, recording and possibility to check the production cycles sustained, keeping traceability and calculating products consumption.

Financials, logistics and enviromental benefits

With the adoption of frozen logistic, the frozen food longer shelf life, there are no risks of late or missing deliveries which revert into turnover loss, as these are mainly issues of fresh/refrigerated logistic. Besides the possibility of better management of stocks,

savings on product waste, there’s also the possibility to save money on deliveries and product purchasing. Oro Koi can offer with it’s own company network, the 4PL business model: we buy on customer’s direction, we process (we can freeze, if requested), we stock, we prepare the product, we deliver it and we invoice it only when the product is being shipped and delivered. Last but not least, the possibility of managing frozen product, not only help in controlling prices and buying during productions peaks, but to respect seasonality of products.

Individual Quick Thawing

Individual Quick Thawing

Oro Koi srl Via Ist. S. Maria della Pietà 21/23 presso polo HUB23 30173, Venezia (VE) – Cel. +39 348 872 3041 info@orokoi.it

![]()

Individual Quick Thawing

Oro Koi srl Via Ist. S. Maria della Pietà 21/23 presso polo HUB23 30173, Venezia (VE) – Cel. +39 3488723041 info@orokoi.it